Experience our top-quality surface finishing services that can enhance the appearance and functionality of your metal parts. Our manufacturing process is unique and comprehensive delivering the best finishing services.

Createproto is the finest in the business at facilitating the best surface finishing services. We offer a varied range of options, fast turnaround times, competitive rates and special expert advice to meet your requirements.

We cater to offer the finest solution to our clients. Based on your needs, you initiate the implementation of the latest technique to ensure the finest outcome.

We absolutely understand that you need your products finished quickly and on time, so we offer fast turnaround times on all of our surface finishing services.

Our team of experts can help you choose the right surface finish for your specific needs and budget. Also, get advice on how to care for your finished products to ensure durability.

From drab to fab, our custom surface finishing service can transform your products. This serves both functional and aesthetic values fostering different requirements.

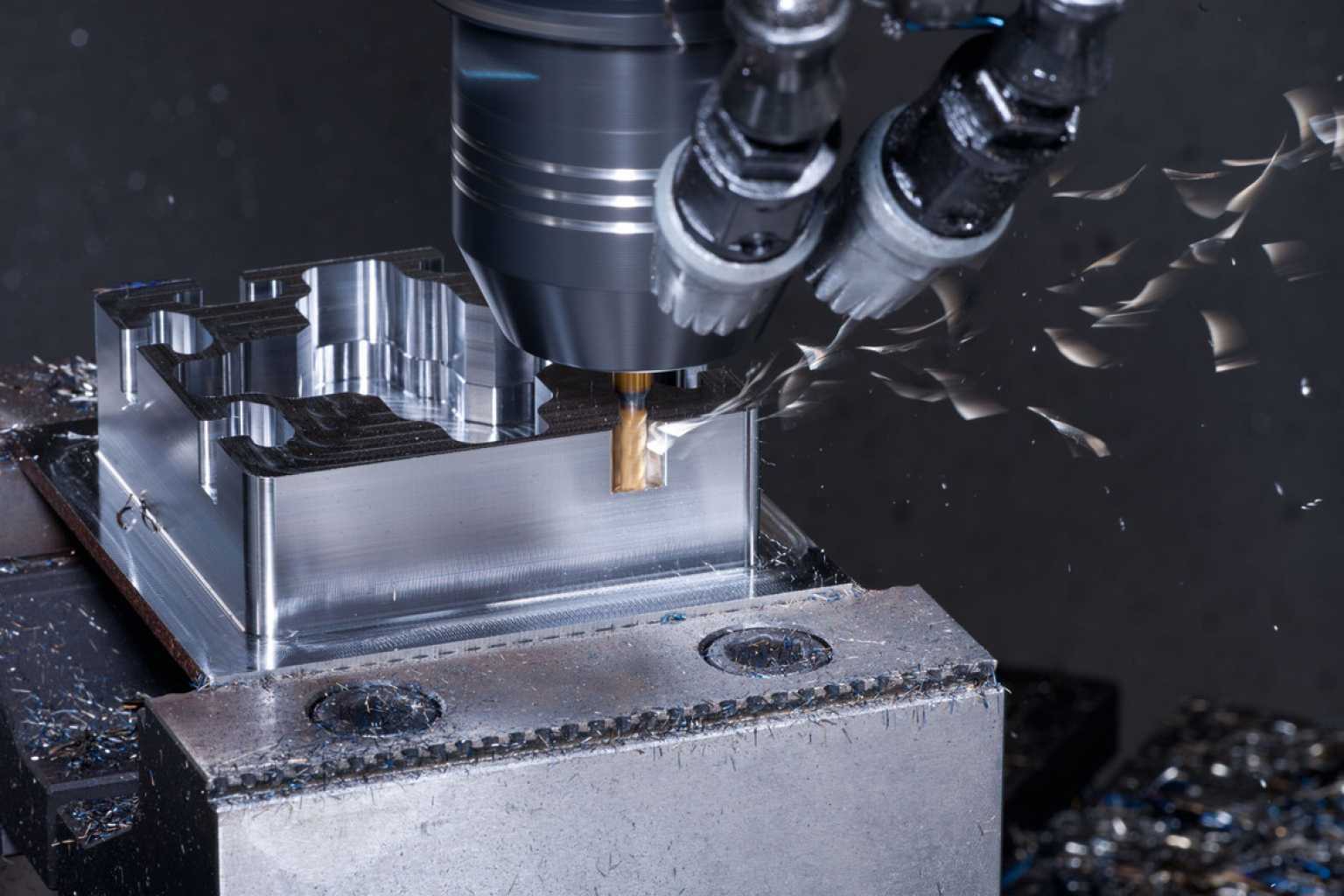

Eradicate sharp edges and rough edges with our standard “as machined” finish. This finishing service with a surface roughness of 3.2 μm (126 μin), leaves your parts looking and feeling their best.

Our bead blasting process propels powerfully with high pressure, a stream of blast media against the surface to remove foreign particles and other impurities.

To ensure durability, our anodizing process resists wear and tear. The process is perfect for surface treatment enhancing the appeal of the manufactured parts.

Our electroplating process helps to preserve the surface parts and resists the formation of rust and destructive issues causing significant decay. We also electric currents to reduce metal erosion.

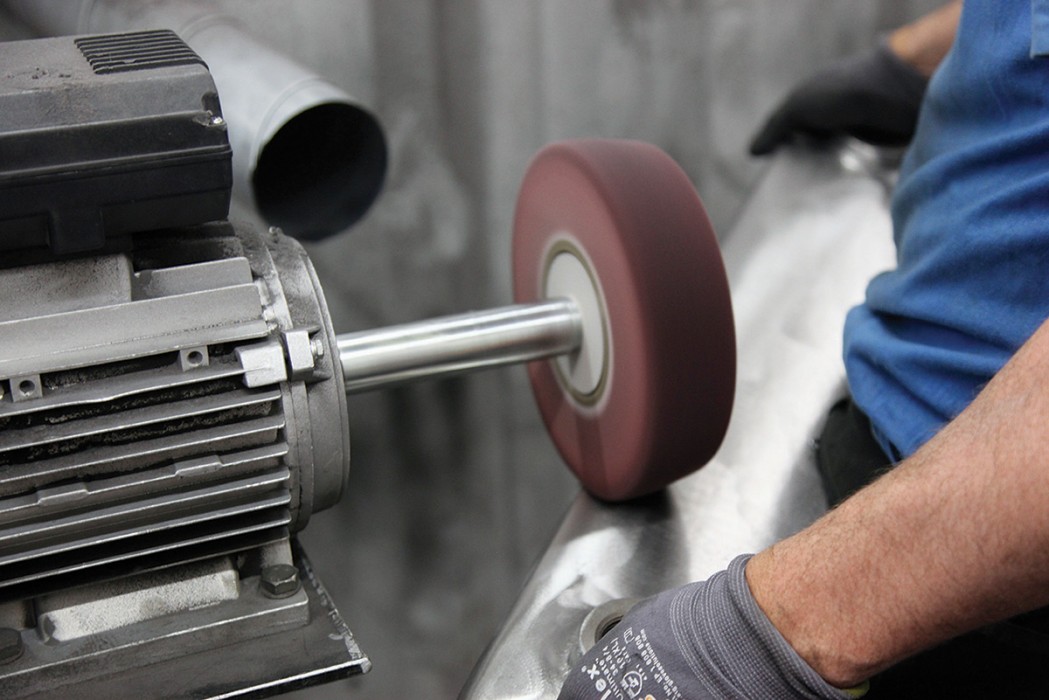

From a subtle glow to a mirror-like finish, our polishing processes can achieve any desired level of shine, catering to your specific needs. Ranging from Ra 0.8~Ra0.1, our polishing service offers the best finish.

With the use of corona discharge, we create powder coating to make the finished product more wear-resistant. Our powder coating process is more resistant to chipping, scratching, and fading than liquid paint finishes.

Our versatile and efficient brushing techniques ensure to improve appearance, functionality, and durability of a wide range of metal products.

Spraying paint over the manufactured metal parts offers unmatchable durability. It offers the best protection to the metal surface from corrosion, wear and abrasion.

Black oxide is a conversion coating that is used to improve the appearance and corrosion resistance of steel and stainless steel. Black oxide is typically applied to steel and stainless steel parts that are used in automotive, aerospace, and industrial applications.

Chromate conversion coating, popularly known as Alodine, is a chemical coating that passivates and shields aluminum from corrosion and wear. It is also used as a base layer before priming and painting parts.

Part marking is a cost-effective way to add logos, custom lettering, or other identifying information to metal and plastic parts.

Get the exact surface finishing services you need, tailored to your specific requirements. Our ISO 9001:2015 certification and manufacturing excellence guarantee your satisfaction.

Get a fast and accurate quote for our precision machining services with just a few clicks. Upload your design to our state-of-the-art instant quotation platform and receive the best pricing and lead time in minutes.

Experience the difference of our clear prototyping services. We use the latest technologies and materials to produce high-quality prototypes with excellent clarity, dimensional accuracy, and surface finish.

Our team of experienced engineers and technicians are experts in clear prototyping. We can help you choose the right material and process for your project, and ensure that your prototypes meet your exact specifications.

It’s been two times we have worked with CreateProto, and honestly, they have never disappointed us. We just requested the quote, and they have handled the rest, from product design to production to testing and launch- All the fulfillment required for our projects so far. Professionalism and convenience- Perfect reasons to work with them!

Avram Mckinney Mechanical Engineer Associate, Thermaco

It’s really impressive working with CreateProto for our automotive projects. Quick responses all the time that has eased communication. We don’t have to manage or juggle suppliers. They got us all covered! In fact, their prices are too competitive, even for mass customization and low-volume production.

Timothy Frederick CAE Mechanical Engineer, BirdOne of the best pre-treatment is alkaline cleaning which involves immersing the surface parts into hot alkaline solution. It helps in removing oils, greases, and other contaminants from the surface.

This is very subject as the amount of material removed depends on various vital factors, such as abrasive, velocity, and duration of the process.

No. Both are different procedures. The former involves the application of chromium while the latter involves the application of nickel to the metal surface.

Whenever and whatever we have needed, Createproto has delivered every time with the exact precision and quality required. Faster turnarounds, perfect finish, and on-time delivery for product launch- Great experience working with them. We appreciate their professionalism and are looking forward to teaming up with them again.

Tyler Richards Lead Mechanical Engineer, Shimano