Take advantage of our network and see what Createproto can do for you.

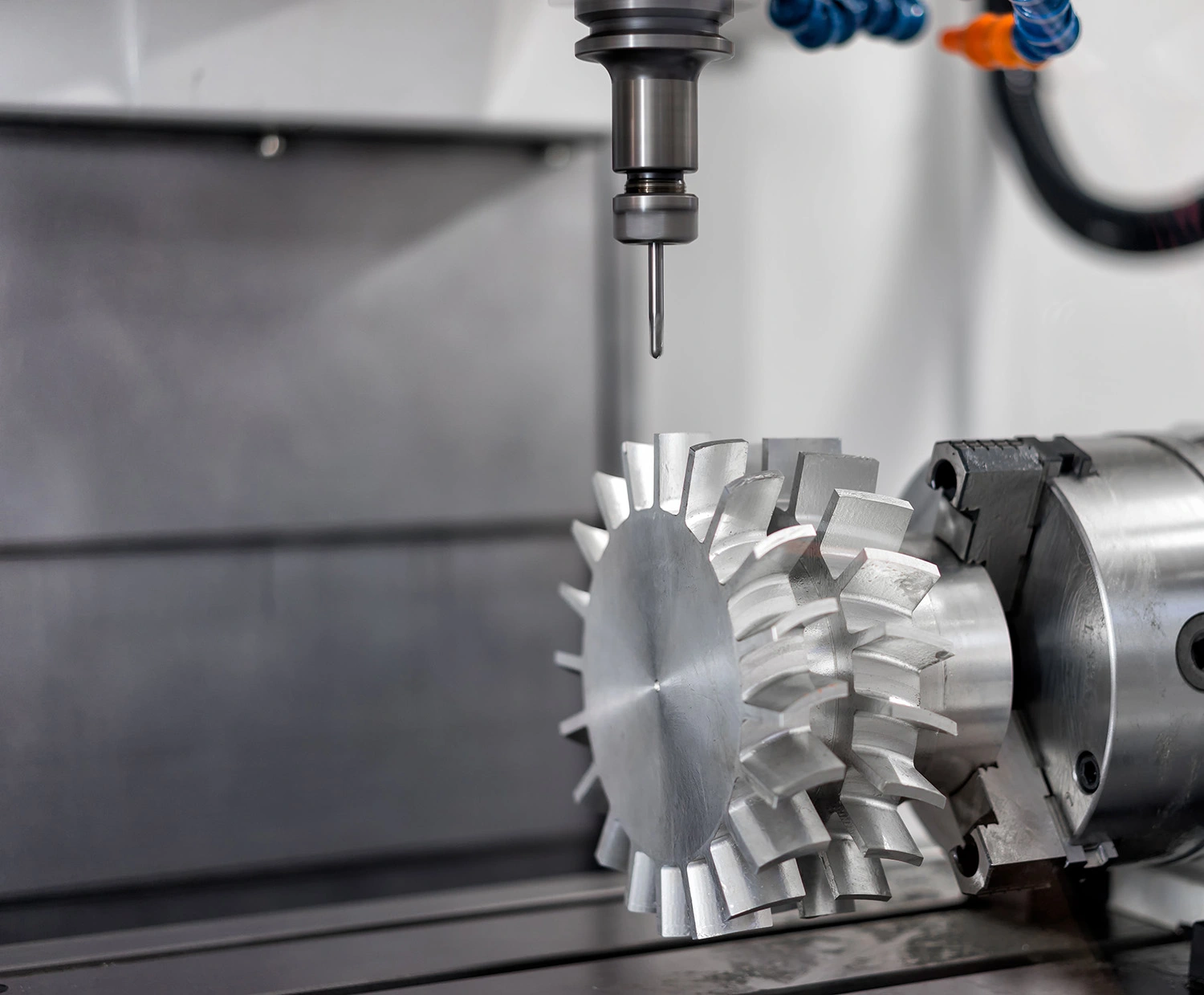

At CreateProto, we have an instant production capacity with an array of capabilities to create different types of CNC machining parts with high precision, from airplane engine parts to medical equipment to machinery components.

With us, It’s just a matter of clicks now. Get a customized quote from our Quick Quote tool. We will assess your product design and get back to you with the estimated charges within 7 hours! You can choose the price and lead time easily now!

Our CNC applications come with the highest precision, making them perfect for different industries, from automotive to medical to aerospace, industrial, transportation, recreational, and even oil and gas sectors.

We use our own tool shop and all our tools are certified within ISO 9001:2015 with temperature-controlled production features. We ensure to develop your product design with the finest detail during injection molding.

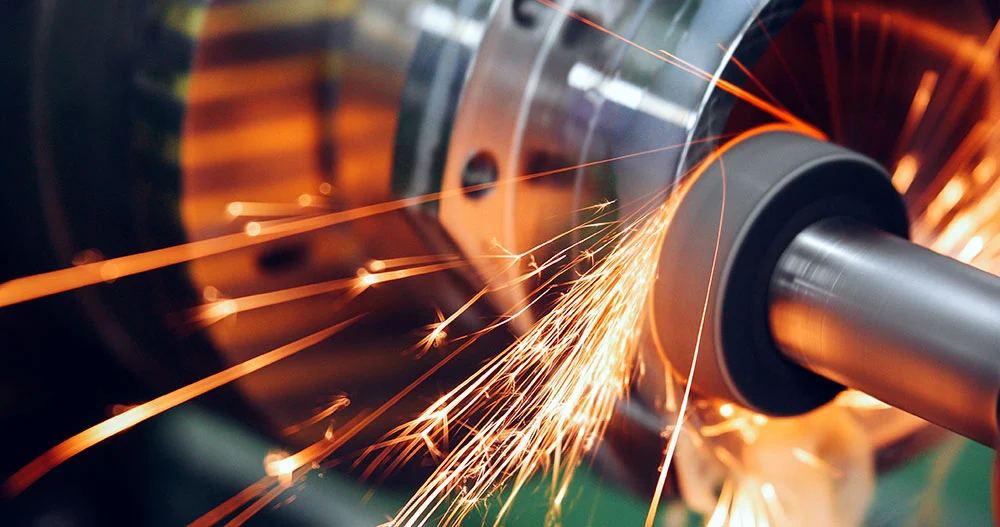

With CreateProto, you can create functional end-use parts for industrial applications, including automotive, medical, aerospace, and much more. Our designers and engineers have the best expertise in developing metals, plastics, and exotic materials using cutting-edge technology, such as CNC machining, CNC turning, and CNC milling services. We strive to deliver precision with CNC machining every time.

Our CNC milling parts come with an industrial look and feel with maximum durability. With our CNC machining process, we support thin features, complex geometries, and large parts.

Our experience and knowledge offer an exceptional combination, providing exclusive custom manufacturing and engineering solutions always on schedule. You can get quotes and design analysis within hours!

Before we start, select a manufacturing process- CNC turning or milling, and upload a 2D or 3D drawing.

After that, we will send you designs, including DFM analysis, with real-time pricing just within a few hours.

Our CNC machining production will begin once you review our quotes and place your order. Also, you can receive finishing options from us.

With our digital manufacturing process, you can rest assured about receiving your parts in just 3 days.

As the leading CNC machining company, our CNC machining and plastic injection molding technology ensures quick product development and optimizes your supply chain at reduced costs. With our smart online quotation platform, Quick Quote tool, you can get instant pricing just within 3 hours on CNC machined plastic and metal parts of the product design you want to get machined.

Our digital manufacturing processes allow part production in over 40 certified materials as fast as 3 days. All you need to upload your product design (2D CAD drawings and 3D CAD models), and our team will get back to you with the estimated price!

We have the ability to create and produce different types of plastic and metal parts in over 40 certified materials. Whether it’s machinery components, airplane engine parts, or medical equipment, you can have us as your trusted partner to design precise products. Our manufacturers use extremely state-of-the-art equipment, such as injection molding presses with multi-shot capability and other cutting-edge tools for robotic pad printing, ultrasonic welding, laser engraving, and metal fabrication services.

From product design to prototyping to production- Our team has years of expertise and experience in all the engineering disciplines and is highly knowledgeable in custom machining services for various sectors, including aerospace, medical, automotive, and much more. We also have the capability to source items for your product completion and perform inspections, assembly, and so on.

No matter what product design you want to get CNC machined, we are here to help you 24/7. We have an experienced and trained in-house engineering design team to provide engineering support round the clock for any technical issues and guidance in case of any complex issues.

You can get our support through emails within 24 hours and even reach out to us for any emergency through call, WhatsApp, or WeChat. You can rest assured and have peace of mind to receive help whenever you need it. With our 24/7 engineering support, you can improve productivity and customer satisfaction while reducing project downtime.

We, CreateProto, are the one-stop solution for plastic and metal part production. We have the perfect team to meet all your manufacturing needs with our quick quoting platform, powerful manufacturing capabilities, and 24/7 engineering support from our in-house engineering design team.

We offer quick lead times and competitive pricing on CNC machining, metal and plastic injection, laser engraving, ultrasonic welding, metal fabrication, and much more. All our tools are ISO 9001:2015 certified. So, reach out to us today to get started, or request your quote right here!

We have been serving clients in various sectors for over a decade, from medical to automotive to aerospace.

We specialize in the automotive industry for designing parts and components for different automotive applications using our rapid prototyping, 3D additive manufacturing, and low-volume production. Our in-house team of engineers ensures an improved CNC machining auto part and assembly through every step, from production to examination and test of the physical prototype. We ensure supply chain flexibility with our rapid tooling, automated quoting of low-volume production parts, and quality digital inspections.

With Rapid Prototyping (RP) and CNC machining for medical devices, we have opened a new door to surgical planning and simulation. Our experts reproduce an anatomical object, showing a realistic impression of complicated structures. We use multiple manufacturing technologies paired with the right equipment, such as bridge tooling, rapid prototyping, and more. We make complex design adjustments to cut the development time and costs, such as low-volume production parts just within two days.

In the aerospace and defense industries, we have set our footsteps. Our experts meet the on-demand production and streamline the supply chain with rapid prototyping. Thanks to our advanced technologies, including automated CNC machining, aluminum CNC milling, 3D printing technology, and aerospace tools and fixtures, to iterate designs faster, prototype final parts, and manufacture complicated geometries quickly. We use only AS9100- and ISO9001-certified machining and 3D printing processes to create parts with precision.

In the consumer electronics market, we strive to meet the demand for innumerable amounts of products and devices, even complex consumer electronics components with our 3D-printed or machined prototyping technology and rapid injection molding for low-volume production to launch your products in the market fast. Also, you can leverage our low-volume production capabilities for mass customization and end-use CNC machining component production for common applications, including housing, lenses, switches, knobs, and so on.

It’s been two times we have worked with CreateProto, and honestly, they have never disappointed us. We just requested the quote, and they have handled the rest, from product design to production to testing and launch- All the fulfillment required for our projects so far. Professionalism and convenience- Perfect reasons to work with them!

Avram Mckinney Mechanical Engineer Associate, Thermaco

It’s really impressive working with CreateProto for our automotive projects. Quick responses all the time that has eased communication. We don’t have to manage or juggle suppliers. They got us all covered! In fact, their prices are too competitive, even for mass customization and low-volume production.

Timothy Frederick CAE Mechanical Engineer, BirdTry out us for machining your parts and see what we can do for you

A team of medical specialists and engineers initiated the development of the latest medical emergency device. They were severely challenged to meet the effectiveness and specifications. Createproto was one of the manufacturers that have successfully accomplished the purpose with rapid production of creating working models of products quickly and affordably. Overall, rapid prototype machining has been observed as a perfect match for developing emergency medical devices.

The evolution of the leading company, Createproto has led to the development of a unique surgical robot that can be utilized to perform a plethora of minimally invested procedures. It is specifically crafted to be less invasive and more precise than traditional surgical methods. Createproto implements their exclusive rapid prototype tooling expertise to bring a dynamic transition to the system.

Our CNC aluminum machining and prototyping technology are the most considered subtractive process for small batch production. Its application isn’t limited to automotive, medical, and aerospace industries but expanded to consumer electronics, oil, and gas sectors. We use the top techniques for CNC machining for different applications, such as functional prototypes, low-volume production, and fixtures and jigs.

With us, you can get instant quotes within seconds on CNC machining. All you need is to upload your product design, and our experts will get back to you within a few hours. For the file formats, we accept a 3D CAD file from other CAD systems output in STEP (.stp), ACIS (.sat), IGES (.igs), or Parasolid (.x_t or .x_b) format, SolidWorks (.sldprt) or ProE (.prt) files, and even .stl files.

At CreateProto, we strive to meet all our clientele demands for low-volume production and rapid tooling in the aerospace, medical, automotive, and consumer electronics industries. We have a wide variety of machines available to produce parts and components with high precision, from lathes to presses, press bakers to 3D printers, CNC milling and turning, EDM, and 3-axis, 4-axis, and 5-axis CNC machining.

If you are looking for a high level of precision and accuracy, you should definitely turn to CNC aluminum service. Its computerized controls generate even complex prototypes as quickly as possible affordably for a single product and small batches. You can rest assured about consistency, repeatability, and material versatility, including plastics, metal alloys, and wood.

Although we charge affordable CNC machined parts, the costs are determined by the complexity of your product design. The cost of CNC-machined parrots is directly proportional to it. The more complex a part is, the longer it will take to machine since there will be a higher number of setups and programming time.

CNC prototype machining includes CNC milling and turning, which are the ideal techniques to provide accuracy and precision to your prototypes for any application. Its computerized controls create an exact replica of the product design from every angle. Moreover, you can get your CNC machined parts and components ready within a week, whereas other injection molding takes a few months.

Rapid prototype machining is the preferred option to design parts and components quickly while involving unique ideas, prototyping, and testing of the physical part using 3D CAD data as per clientele demands. It’s the best choice for short-run manufacturing of large parts in different industries, from automotive to aircraft and shipbuilding sectors.

Our rapid prototyping services combine conventional and rapid tooling practices to create mold designs and produce model parts faster. At CreateProto, we use rapid prototype machining in injection molding to produce parts and components in thousands at a time across industries, which means less time and reduced production costs.

Need a Quote? If you are looking to order prototype parts, then look no further, get in touch with us for all manufacturing and engineering services. Our experts will get back to you to fulfil your needs.

Whenever and whatever we have needed, Createproto has delivered every time with the exact precision and quality required. Faster turnarounds, perfect finish, and on-time delivery for product launch- Great experience working with them. We appreciate their professionalism and are looking forward to teaming up with them again.

Tyler Richards Lead Mechanical Engineer, Shimano